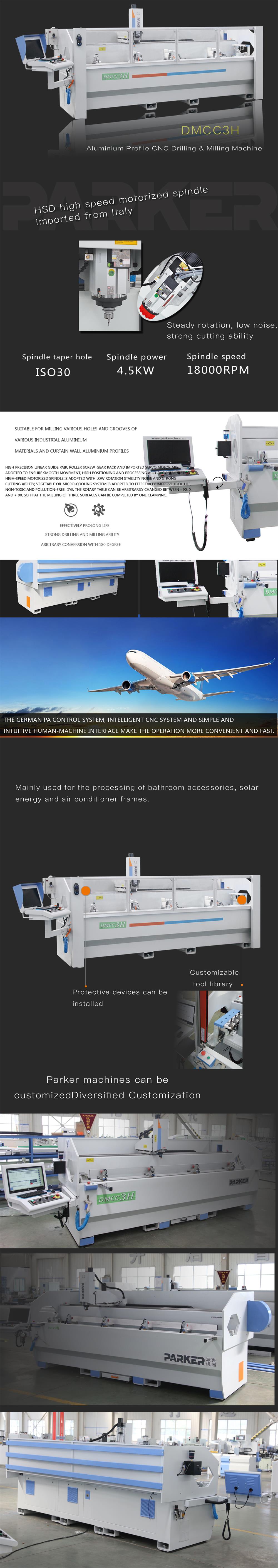

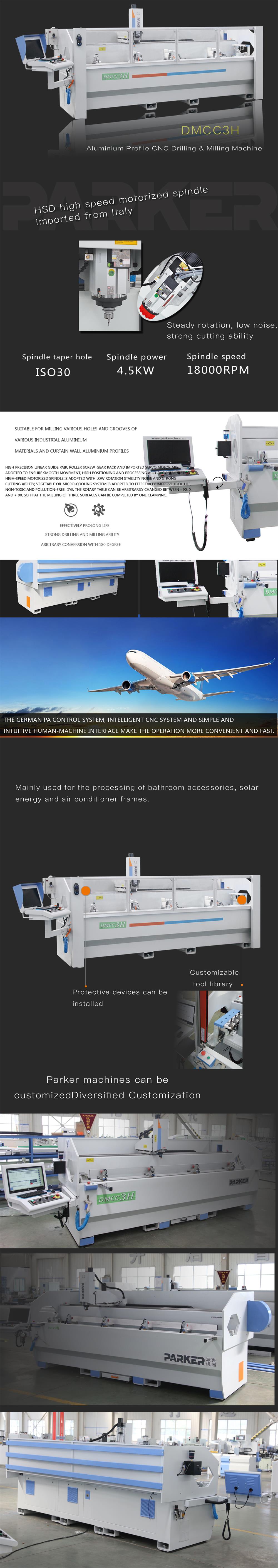

Three axle high speed heavy load machining center

Using high precision linear guide rail pair, roller screw, gear rack and imported servo motor to ensure smooth movement, high positioning and machining precision, using Italy HSD high-speed electric spindle, small rotating noise and strong cutting ability, using plant oil micro cooling system, effectively improve tool life, non-toxic and non pollution. Dyed. The rotatable worktable can be converted to any other three positions at -90 degrees, 0 degrees and +90 degrees, so that once the clamping is completed, the milling of three faces can be completed.

TECHNICAL DATA.

STROKE |

Stroke for X axis | 3200mm |

Stroke for Y axis | 300mm |

Stroke for Z axis | 200mm |

SPINDLE |

Spindle Speed | 18000 RPM |

MOVING SPEED |

X Axis Moving Speed | 140m/min |

Y Axis Moving Speed | 75m/min |

Z Axis Moving Speed | 75m/min |

X/Y/Z Feeding Speed | 0~2000mm/min |

POWER OF MOTOR |

X/Y/Z Driven Motor | 0.85kw、0.75kw、0.75kw |

|

|

|

LUBRICATING SYSTEM |

Cooling System | SAGELY |

PRECISION |

Position Precision Of X Axis | ±0.05mm |

Position Precision Of Y /Z Axis | ±0.02 mm |

Repeating Position | ±0.02 mm |

SIXE OF MACHINE |

Power Supply | AC 380V 50Hz |

Power | 4.5kw |

Air Pressure | 0.5MPa – 0.8MPa |

Weight | 3t |

Area | 4525mm×1630mm×1900mm |

MAIN COMPONENT CONFIGURATION |

Operation System | PA |

Serve Motor | Ankawa |

Spindle Motor | HSD |

Guide Rails | THK |

Bearings | NSK |

Ball Screw | TBI |

Electrical Parts | Schneider |

Reducer | liming |