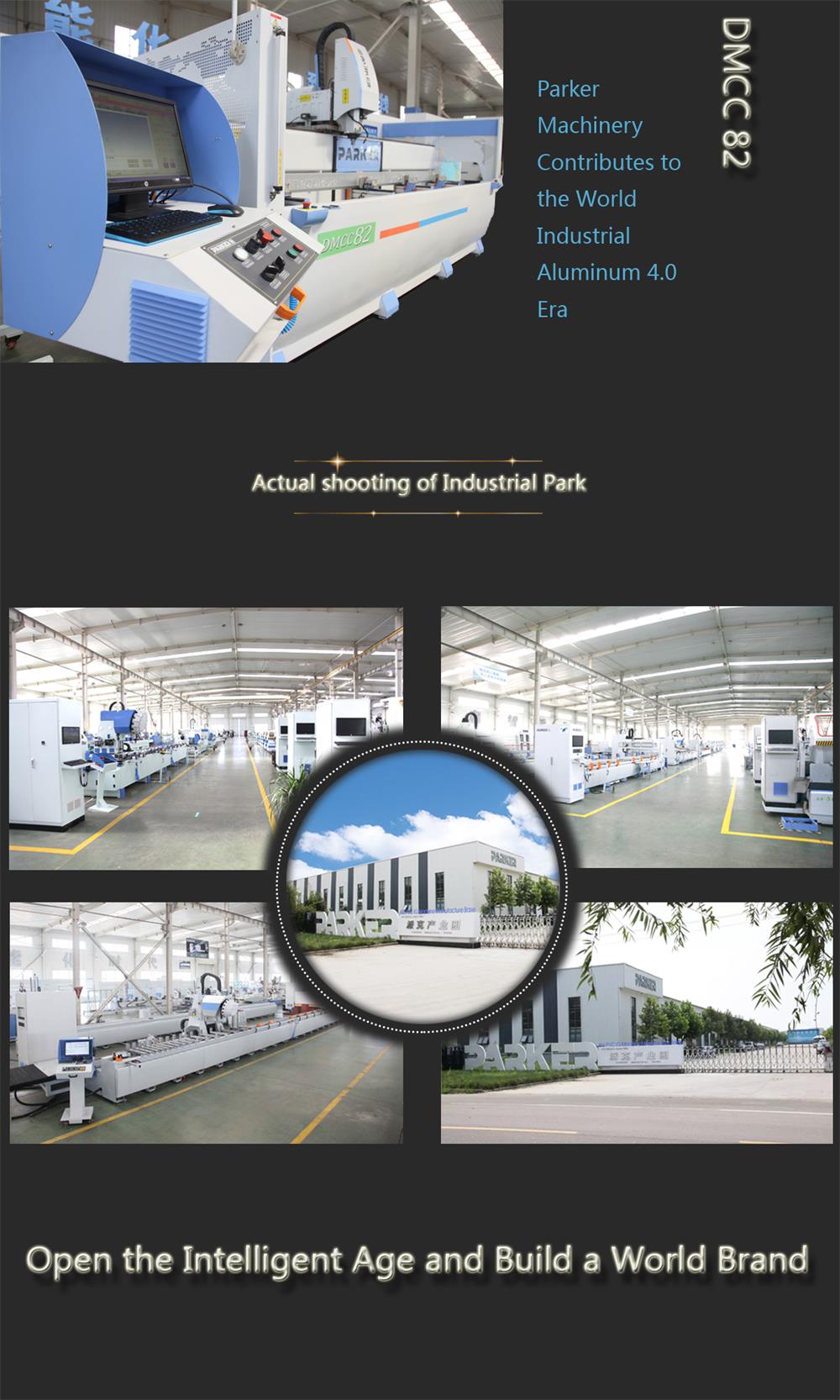

Model :DMCC82

Description

DMCC82 high-speed drilling-milling processing center is equipped with SCHNEIDER brand servo motor control system, ensuring high quality. Equipped with professional CAM processing software and intuitive programming system, this CNC profile machining center enables easy visualization of complex processing. This curtain wall drilling-milling processing center is designed for processing mounting hole, launder, lock hole and screw on various curtain wall profiles made of aluminum, light alloy or UPVC.

Use

This CNC profile machining center is used for window-door, curtain wall, aluminum profile, rail transportation, refrigeration components, bathroom hardware, ship building and ship repair, aluminum bronze accessories, etc. DMCC82 drilling-milling processing center can also be applied for industrial aluminum, nonferrous metal and light section steel structure, and so on.

TECHNICAL DATA.

STROKE |

Stroke for X axis | 3500mm |

Stroke for Y axis | 400mm |

Stroke for Z axis | 400mm |

SPINDLE |

Spindle Speed | 18000 |

TOOLS |

Tools Changer Format | straight |

Capacity Of Tools Magazine | 8 |

Tool Change Time | 5s |

MOVING SPEED |

X Axis Moving Speed | 100000mm/min |

Y Axis Moving Speed | 80000mm/min |

Z Axis Moving Speed | 60000mm/min |

X/Y/Z Feeding Speed | 0-2000mm/min |

POWER OF MOTOR |

Spindle Driven Motor | 5.5kw |

X/Y/Z Driven Motor | 1.3Kw 1.5Kw 1.0Kw |

|

|

|

LUBRICATING SYSTEM |

Lubricating System | BAOTENG |

Cooling System | SAGELY |

PRECISION |

Position Precision Of X Axis | ±0.05mm |

Position Precision Of Y /Z Axis | ±0.02mm |

Repeating Position | ±0.02mm |

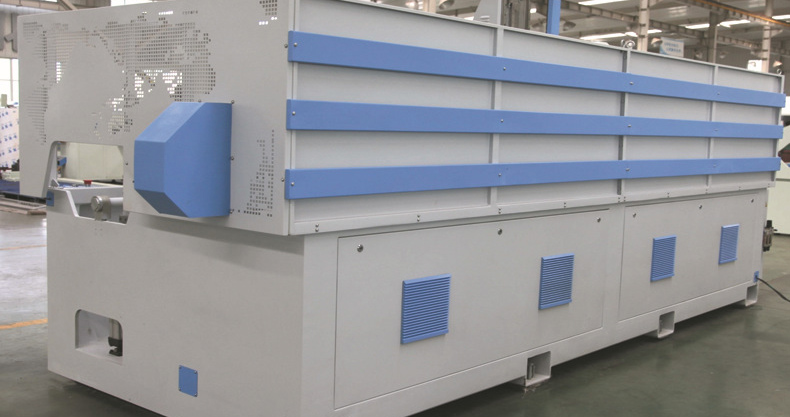

SIXE OF MACHINE |

Power Supply | AC 380V 50Hz |

Power | 11KW |

Air Pressure | 0.5MPa – 0.8MPa |

Weight | 3t |

Area | 5350*1800*2500mm |

MAIN COMPONENT CONFIGURATION |

Operation System | SYNTEC

|

Serve Motor | YASKAWA |

Spindle | HSD |

Guide Rails | THK |

Bearings | NSK |

Ball Screw | TBI |

Electrical Parts | Schneider |

Pneumatic Components | AIRTAC |

Reducer | ATG |