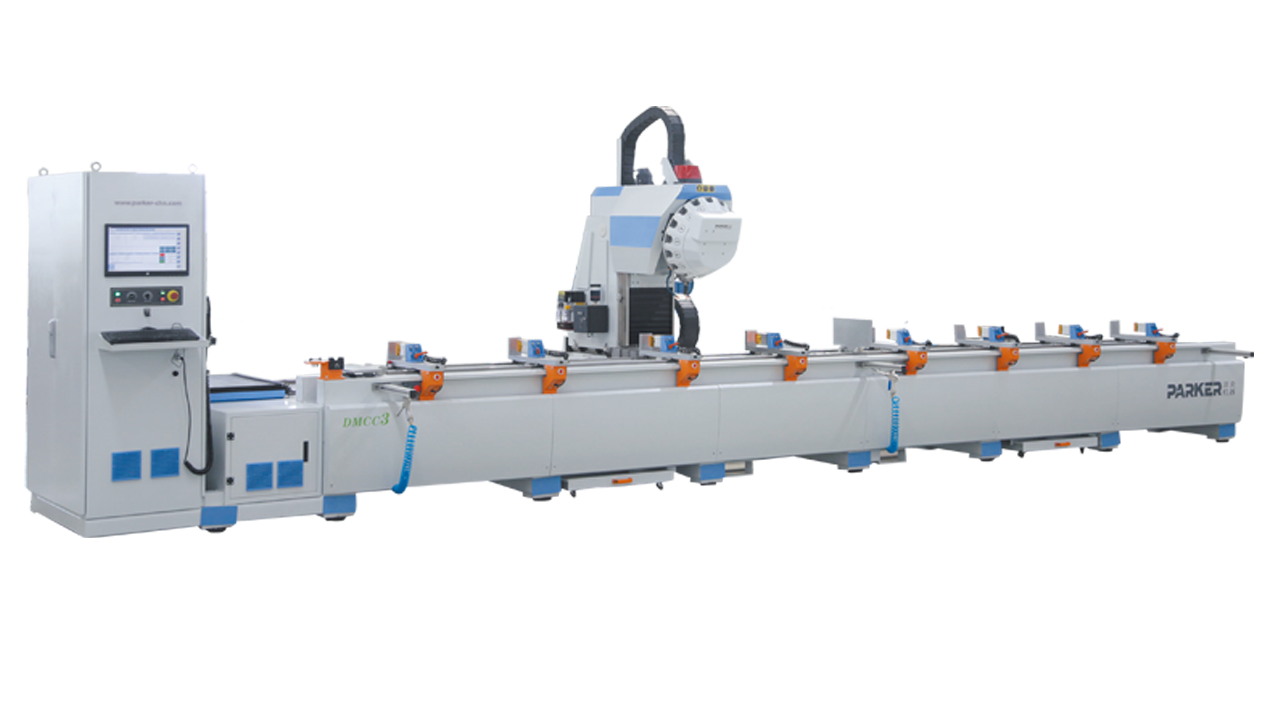

Model: DMCC3

Features:

Ø Steel, iron, aluminum, copper and other materials can be processed.

Ø Integrated design of electrical cabinet and machine body makes transportation , installation ,operation much easier,and the stability more higher.

Ø Equipped with crumb guide device, aluminum and steel crumb will be gathered at bottom drawers, which makes clean much easier.

Ø Double-location design with very high efficiency, more work locations can be increased according to customer requirements.

Ø X, Y, Z axis max. positioning speeds can be up to 80M, 60M, 60M / min, which is fastest speed in similar machine among this field.

Ø Imported pneumatic circuits for clamping device, make holders have a greater lateral movement range, suitable for processing different profiles.

Ø Point control for holder brake, workers can move and locate clamping device much easier.

Ø Equipped with SAGELY micro lubrication system (USA), vegetable lubrication oil, non-toxic, non-pollution, effectively protect milling tools and increase tool life.

Ø Spindle adopts GELLS brand ( Taiwan ), maximum speed up to 12000Rpm.

Ø With rigid tapping function, much faster and precise,

Ø Servo spindle motor can output max. 23.9Nm during low-speed, speed up to 11000rpm, fully suitable for heavy steel, copper and aluminum profiles.

Ø Imported Fanuc Japan/ German PA/ German Siemens/Taiwan Syntech Control system is equipped with standard hole database, workers can select graphics and input coordinate directly, with simple operation. For complex or non-standard graphics, workers can process with CADCAM which is equipped on machine.

Ø Tool presetting is not needed before exchange tools, tool length can be input into CADCAM system for process, much easier and efficient.

Ø Automatic crumb cleaning device ( Optional ).

Ø Barcode scanner to scan labels on profiles, fit using CIMS system, to save labor, reduce error and improve production efficiency (optional ).

Technical Parameter:

X axis Stroke: 7300mm

Rapid positioning speed(X axis) :80m/min

Y axis Stroke: 300mm

Rapid positioning speed(Y axis):60m/min

Z axis Stroke: 380mm

Rapid positioning speed(Z axis) :60m/min

Tool Magazine:16 (can be order)

Spindle max.rotary speed: 11000RPM

Air Pressure: 240L/min

Processing Area:(LxWxH): 7300x380x300mm

Voltage: 380V 50HZ(As customer required)

Power: 13KW

Main Spindle Power: 5.5KW

Dimension:(LxWxH) : 9900x2250x2560mm